one-stop online platform

Covering procressing, surface treatment, packaging, and transportation for seamless production.

Precision Machining Hub

A global leader in precision machining, Taichung drives CNC innovation and excellence in manufacturing.

Strict Quality Assurance

All suppliers are personally vetted and approved, ensuring strict quality control for your peace of mind.

About us

As a multispecialty supplier specializing in mechanical component solutions, Kuma Technology is committed to providing customers with the shortest lead time and the highest quality customized parts.

Established in Taichung, the hub of Taiwan’s precision machining industry, we aim to connect Taiwan’s precision manufacturing ecosystem to meet the global demand for efficient and high-quality components.

Our goal is to help Taiwanese machining factories secure international orders, expand their revenue, and achieve a win-win scenario.

A few things we’re great at

Our Services

We are continuously building a one-stop online platform for customized parts, catering to customers worldwide. By aggregating orders from across the globe, we provide tailored solutions and utilize Kuma-certified supply chains to match orders with the most suitable machining factories. Each product undergoes strict quality control by Kuma’s professional inspection team before being delivered to customers.

Our platform eliminates communication barriers between customers and manufacturers, ensuring that clients receive the best-quality products with minimal effort and time investment. At the same time, we help Taiwan’s traditional industries secure overseas orders, fostering growth and sustainability for all stakeholders.

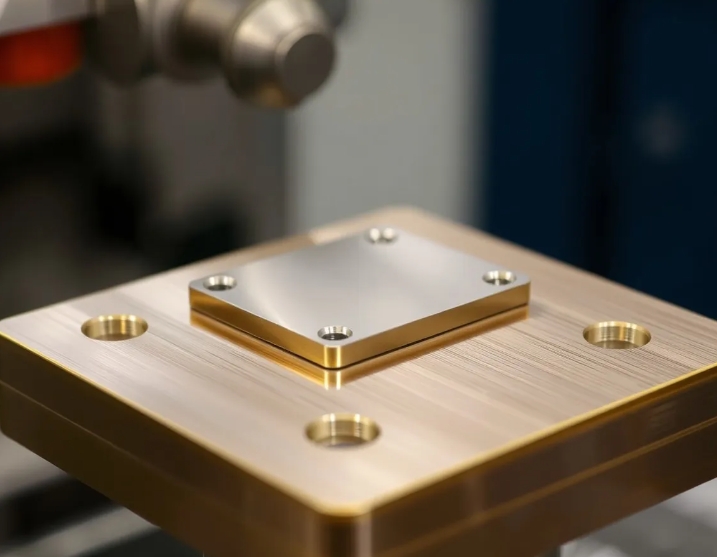

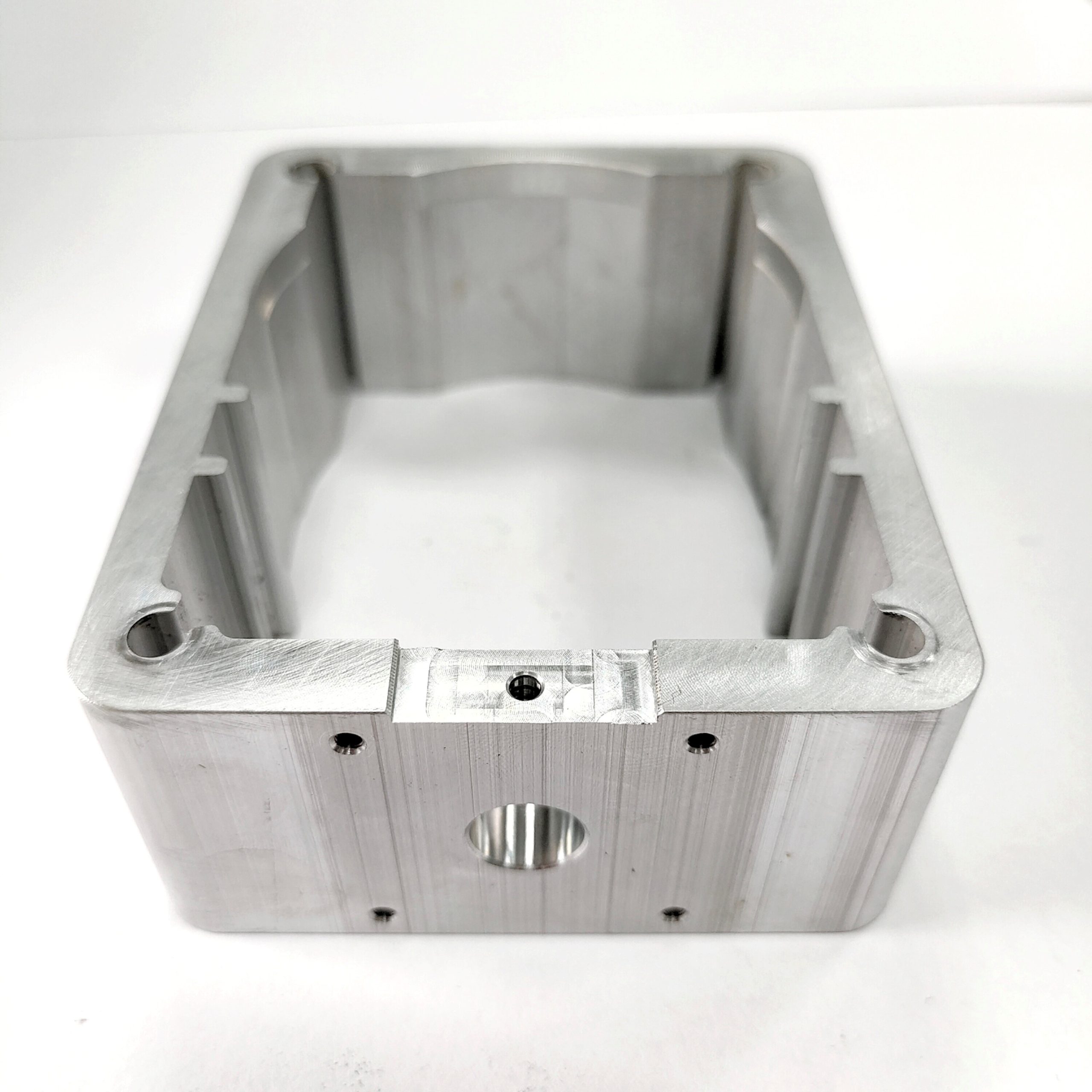

CNC Machining Service

We provide comprehensive CNC machining solutions, including milling, turning, mill-turn, wire and sinker EDM, grinding, gear hobbing, gun drilling, casting, and mold making. With tight tolerances, high precision, and strict quality control, we ensure efficient production for high-mix, low-volume, and complex machining needs.

Surface Treatment

We offer a wide range of surface finishing solutions, including anodizing, plating (gold, silver, zinc, electroless nickel), powder coating, bead blasting, black oxide, chem-film, passivation, electropolishing, heat treatment, polishing, and brushing. These processes enhance corrosion resistance, durability, aesthetics, and functionality.

Metal Materials

We offer a wide range of industrial-grade metals, including aluminum, copper, stainless steel, titanium, tool steel, and nickel alloys, suited for high-strength, corrosion-resistant, and high-temperature applications in aerospace, automotive, medical, electronics, and precision machining industries.

Our Gallery

Explore our collection of images showcasing our precision machining and fabrication work.

Auto Parts

Bicycle Parts

Drone parts

Handly Tools

Sporting Equipment Components

3C Components

Our Blog

Showcasing the latest news, manufacturing trends, and industry insights for innovation and growth.

Exploring Seng Hsu Industrial Co., Ltd.: Where Motor Innovation Meets Community Impact

Today, we had the privilege to visit Seng Hsu[…]

Visiting Liy Cheng: Setting the Benchmark for Ultra-Precision Manufacturing

Recently, we had the opportunity to visit Liy Cheng[…]

⚙️ Behind the Gearbox: Visiting REGAL MACHINERY CO., LTD. 🏭

Last week was all about precision, power, and a[…]

🏭【Kuma Vlog】Precision in Wax: Visiting Shinyih Precision Industrial 🔩✨

Discovering Taiwan’s lost wax casting specialists with […]

🎬 [VLOG] Lessons from Taiwan’s Silicon Powerhouse: Decision Science and Automation at TSMC, through the Eyes of VP Liu Chun-Ming

Yesterday at National Tsing Hua University, we had the[…]

Exploring the Future of Manufacturing: A Visit to Chung Yuan University’s Smart Manufacturing Center

Today’s visit to Chung Yuan Christian University’s Smar […]

Contact Info

Contact Us

Get in touch with us to discuss your design needs.